EarthElements™ Safety Data Sheet

Safety Data Sheet

Version 1.0 Issued March 1, 2025

Page 1 EarthElements™ SDS 2025 03 01

Publication date: March 1, 2025

This SDS adheres to the standards and regulatory requirements of the United States and may not meet the regulatory requirements of other countries.

Section 1. Product and Company Identification

|

Product name |

EarthElements™ |

|

MSDS Number |

ZQE20240901 |

|

Company name of supplier |

ZQ Surfaces, Inc. and/or ZQ Surfaces Corp. |

Restrictions on Use: For recommended applications as a surfacing material.

Section 2. Hazards Identification

Emergency Overview

The product as such is not hazardous. The hazards of this product are associated mainly with its processing. Operations such as sawing, routing, drilling and sanding can generate dust. Wet dust generated during fabrication of Composite Products is non-hazardous. Mixture is judged to be non-hazardous based on known acute toxicity of ingredients it may contain.

Warning symptoms:

Potential Health Effects:

Eyes: ———– Wet or dry dust contact with the eyes can lead to mechanical irritation

Inhalation: — Gross overexposure may cause: Breathing difficulties, Fever, Cough, and possibly Lung damage. May be fatal if inhaled in large quantities. Follow OSHA safety guidelines for Personal Protective Equipment (PPE) to be worn during conversion of slabs.

Section 3. Composition/Information on Ingredients

Component Information/Information on Non-Hazardous Components

|

CAS # |

Component |

Percent |

|

65997-18-4 |

Frit Glass |

Proprietary |

|

13463-67-7 |

Titanium Dioxide (TiO2) |

Proprietary |

|

113669-95-7 |

Unsaturated Polyester Resin |

Proprietary |

|

Inorganic Fillers |

Proprietary |

Frits (CAS# 65997-18-4) are a mixture of inorganic compounds that are melted together, rapidly cooled to produce flakes and may then be milled to form powders. This product contains hazardous components that are essentially insoluble. The substance’s nature greatly or totally reduces the hazards of the ingredients.

Section 4. First Aid Measures

First aid measures are not required when exposed to just slabs of material.

Always seek medical assistance if necessary or if you have questions. In situations of exposure to particulates when cutting, grinding, machining the slabs, always follow OSHA or State guidelines for exposure limits and the wearing of Personal Protective Equipment!

Health Reminders:

Inhalation issues: Move individual to fresh air, seek medical assistance if individual experiences breathing difficulty.

Skin contact: Wash exposed areas with soap and water.

Eye contact: Flush eyes with water for at least 5 minutes. Do not rub eye. Seek Medical attention if individual experiences irritation after eye flushing.

Ingestion: Material is non-hazardous.

Protection of First aiders: No applicable data available

Notes to Physicians: No applicable data available

Section 5. Fire-fighting measures

Suitable Extinguishing Media: The product itself does not burn. Use extinguishing measures that are appropriate to local situation and circumstances and the surrounding environment.

Hazardous Combustion Products: If heated to excess temperatures, this material will proceed to a liquid and will form irritating and toxic gaseous metallic oxides at extremely high temperatures.

Firefighting Instructions: Wear full protective clothing, including helmet, self-contained positive pressure or pressure demand breathing apparatus, protective clothing and face mask.

Section 6. Accidental Release Measures

NOTE: Review FIRE FIGHTING MEASURES and HANDLING (PERSONNEL) sections in this document before proceeding with clean-up. Use appropriate PERSONAL PROTECTIVE EQUIPMENT during clean-up as recommended.

Safeguards (Personnel) – Wear personal protective equipment.

Spill Cleanup – Not applicable

Accidental Release Measures – Not applicableion Products: If heated to excess temperatures, this material will proceed to a liquid and will form irritating and toxic gaseous metallic oxides at extremely high temperatures.

Firefighting Instructions: Wear full protective clothing, including helmet, self-contained positive pressure or pressure demand breathing apparatus, protective clothing and face mask.

Section 7. Handling and Storage

Storage: Material does not require special storage instructions. It is recommended material be stored in an area protected from the environment.

Handling: Wear appropriate Personal Protective Equipment such as hand protection and footwear.

Wash hands before breaks and at the end of the workday.

Section 8. Exposure Controls/Personal Protection

The product is composed of inorganic mineral fillers. The occupational exposure levels are provided for information purposes. Consult a health and safety professional or local authorities if you have questions.

Engineering controls: Provide appropriate exhaust ventilation at places where dust is formed.

Exposure Limit Values: Not appropriate for material shipped from manufacturer. When cutting or grinding, for example, workers should seek from their employer appropriate personnel protective equipment as required by the government, the work environment conditions and equipment to process the material safely.

Personal Protective Equipment (PPE)

Eye/Face protection: Wear appropriate safety glasses with side shields

Hand Protection: For additional protection, wear protective gloves.

Foot Protection: Safety shoes are recommended when handling material.

Respiratory Protection: In case of insufficient ventilation, wear suitable respiratory equipment. Respiratory protection is required under normal use of this product where there are cutting or grinding operations that may generate wet dust. It is required that all manufacturing operations be done in wet conditions. Respiratory protection is necessary even if engineering controls are used to reduce wet dust generation during cutting or grinding operations. If respiratory protection is deemed necessary from exposure monitoring data, follow OSHA regulation 29 CFR 1910, 134 or other local regulations. Always use a NIOSH or other approved respirator when necessary.

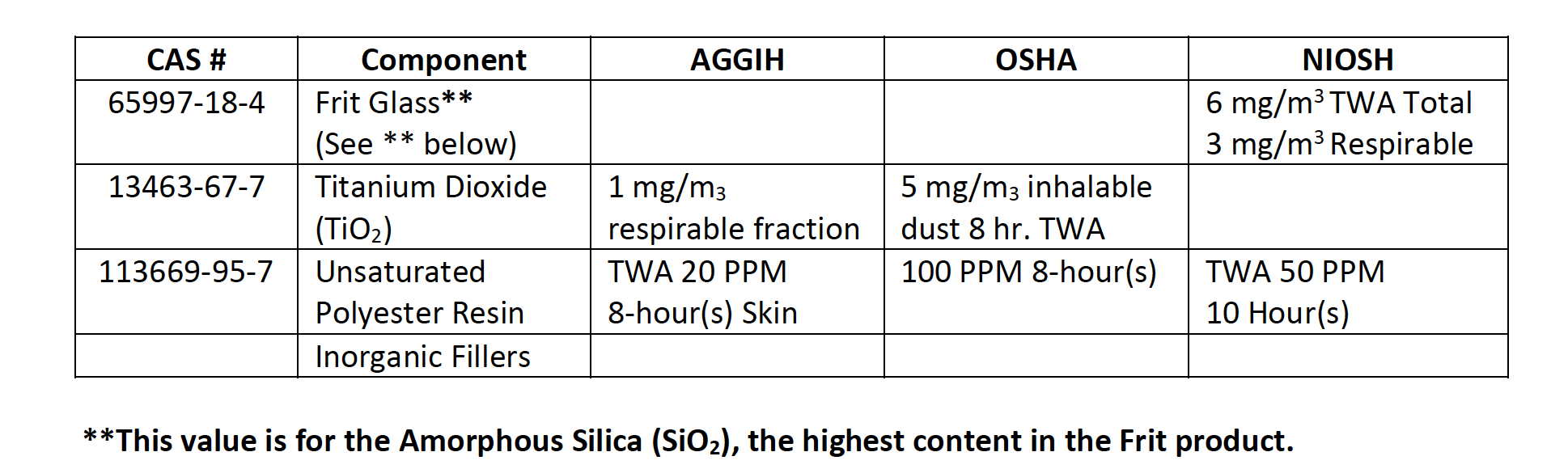

Exposure Guidelines – Exposure Limit Values

Section 9. Physical and Chemical Properties

Form: Solid

Color: Various

Odor: None

Density: 2.2 – 2.5 g/cm3

Water solubility: Insoluble

Section 10. Stability and Reactivity

Reactivity – No applicable data available

Chemical stability – No applicable data available

Possibility of Hazardous reactions – None foreseen

Conditions to avoid – None foreseen

Incompatible materials – No applicable data available

Hazardous decomposition products – No decomposition occurs if used as directed.

Section 11. Toxicological Information

Acute Toxicity

A: General Product Information

No information available for product. As supplied, this product has limited bioavailability, however upon ingestion or inhalation, these elements may slowly dissolve out.

Silicon dioxide (amorphous) dust seems to have little adverse effect on lungs and does not appear to produce significant organic disease or toxic effects when exposures are kept under reasonable control.

A: Component Carcinogenicity

Silicon dioxide, amorphous (7631-86-9)

IARC: Monograph 68, 1997 (Group 3 (not classifiable))

Epidemiology

No information available.

Neurotoxicity

Some reports of neurological effects due to boron (ingested by infants as boric acid) have been reported.

Mutagenicity

No information available.

Other Toxicological Information

Under normal conditions of use for glass products, the likelihood of inhaling or ingesting amounts necessary for these effects to occur is very small. Persons with preexisting eye and skin conditions or impaired pulmonary function may be more susceptible.

Section 12. Ecological information

This product has no known ecotoxicological effects.

Section 13. Disposal Considerations

Waste disposal methods should follow local regulations.

Section 14. Transport Information

This product is not regulated as dangerous under transport regulations.

The information provided in this Safety Data Sheet is correct to the best of our knowledge, information and belief at the date of its publication. The information given is designed only as a guidance for safe handling, use, processing, storage, transportation, disposal and release and is not to be considered a warranty or quality specification. The information relates only to the specific material designated and may not be valid for such material used in combination with any other materials or in any process, unless specified in the text.

Section 15. Regulatory Information

The finished product is not regulated.

Section 16. Other Information

The information provided in the Safety Data Sheet is correct to the best of our knowledge, information and belief at the date of publication.